6 min read

Hot Stamping Polypropylene Parts at AFM Engineering

When silk-screened marks start failing in the field, it's rarely the ink that gets blamed first. Production teams troubleshoot pre-treatment...

Check out our articles about direct part marking, how to mark different materials, application stories from our customers, and much more.

6 min read

When silk-screened marks start failing in the field, it's rarely the ink that gets blamed first. Production teams troubleshoot pre-treatment...

4 min read

Stainless steel fights back when you try to mark it. The material's work-hardening characteristics and high strength create challenges that don't...

2 min read

PakLab, LLC operates from their Batavia, OH facility, where they've carved out a specialized niche designing and delivering flexible packaging...

4 min read

In today's manufacturing landscape, part marking has evolved far beyond simple identification. As industries push boundaries with advanced materials...

3 min read

In the world of manufacturing and industry, marking and identification play a crucial role. From tracking products throughout the supply chain to...

1 min read

Permanent marking on metal, whether stainless steel, aluminum, titanium, brass, or copper, presents a couple of unique challenges but can be...

2 min read

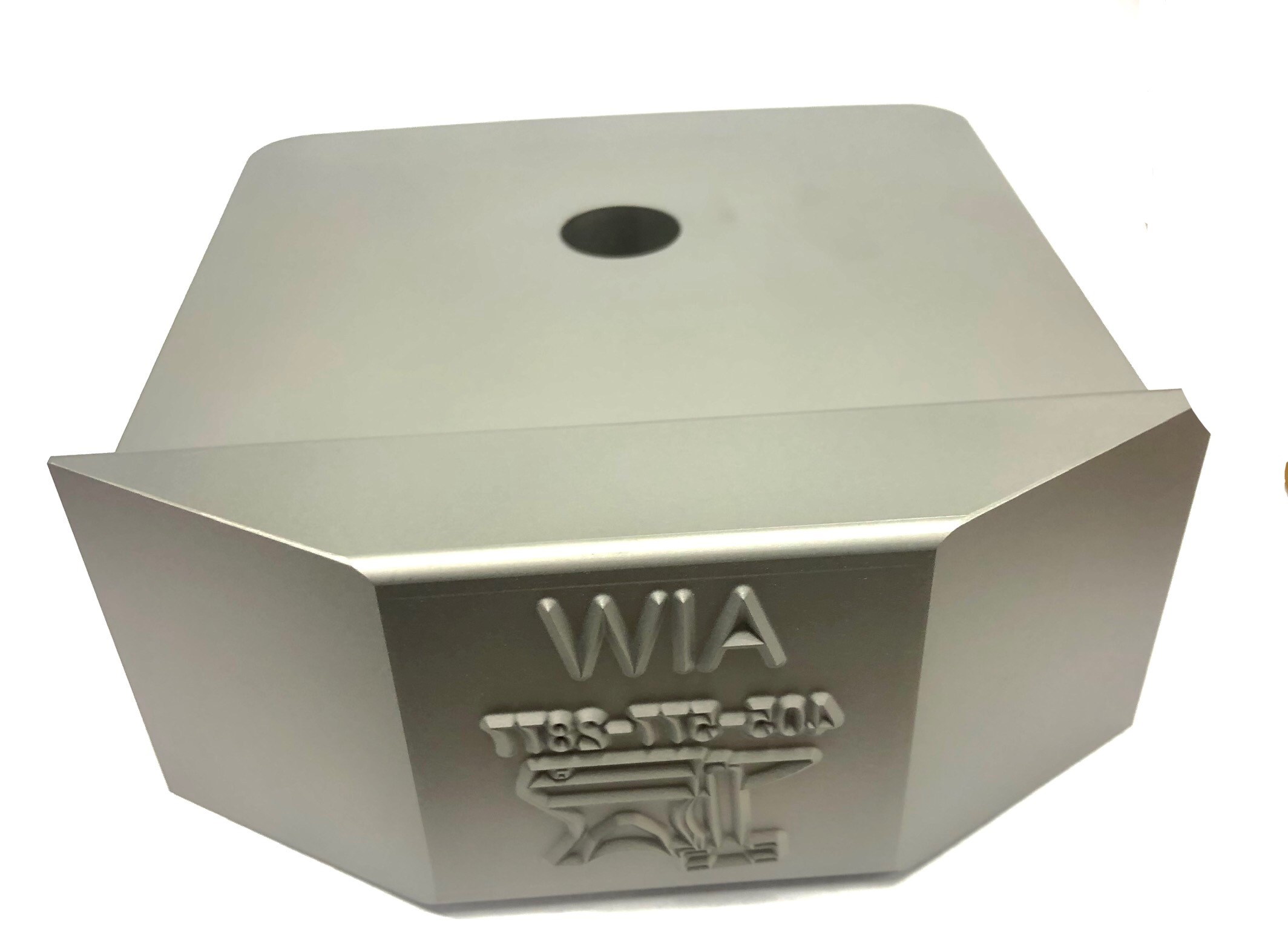

Durable Technologies' customers continually push us to discover new and creative ways to address challenges in the process of identifying parts....

1 min read

For small businesses, craftsmen, and artisans, direct part marking customization is an excellent way to differentiate their products.

2 min read

Steel stamps provide a means to permanently mark metal parts and products with identifying information such as serial numbers, part numbers, model...

2 min read

Durable Technologies' pneumatic impact presses are simple to set up, easy to operate, and offer excellent repeatability. They provide significant...