When ROYCE needs to create lasting impressions on its luxury leather goods, it turns to precision hot stamping technology. Since 1974, this Secaucus, NJ-based family business has built its reputation on delivering memorable custom leather goods with flawless branding. Their tagline "Branding Your Business, Literally" captures both the marketing impact and the physical permanence of their marking process.

The stakes are high in luxury goods manufacturing. When companies invest in premium products, the quality of every detail matters. The brand mark on a leather product serves as both a signature of authenticity and a testament to craftsmanship. This is where the intersection of traditional marking methods and modern precision becomes critical.

What Makes Hot Stamping Essential for Luxury Leather Goods?

Hot stamping represents the gold standard for permanent marking on leather products. Unlike printed labels or surface treatments that can wear off, hot-stamped impressions create lasting marks that actually become part of the material. The process involves heating a custom-engraved die and pressing it into the leather surface, creating a permanent depression that showcases logos, text, or decorative elements.

For luxury goods manufacturers, hot stamping delivers several critical advantages. The process creates crisp, clean lines that maintain their definition through years of use. Each impression maintains consistent depth and clarity, essential for brand recognition. The permanence of hot stamping also serves as an anti-counterfeiting measure, as the precise tooling and technique are difficult to replicate without access to original dies and proper equipment.

The tactile quality of a hot-stamped mark adds to the perceived value of luxury items. Customers can feel the impression, creating a sensory connection with the brand that goes beyond visual identification. This physical dimension of branding becomes particularly important in markets where authenticity and craftsmanship drive purchasing decisions.

How Does Royce Use Hot Stamping Dies for Premium Branding?

Royce Leather Gifts has integrated hot stamping die technology throughout their production process. Their partnership with Durable Technologies' VisiMark division enables them to maintain the exacting standards their clients demand. William Bauer, Managing Director at Royce, emphasizes the critical nature of this relationship: "We have never seen brass hot stamp dies for our Kwikprint machines hold up like the ones from VisiMark do."

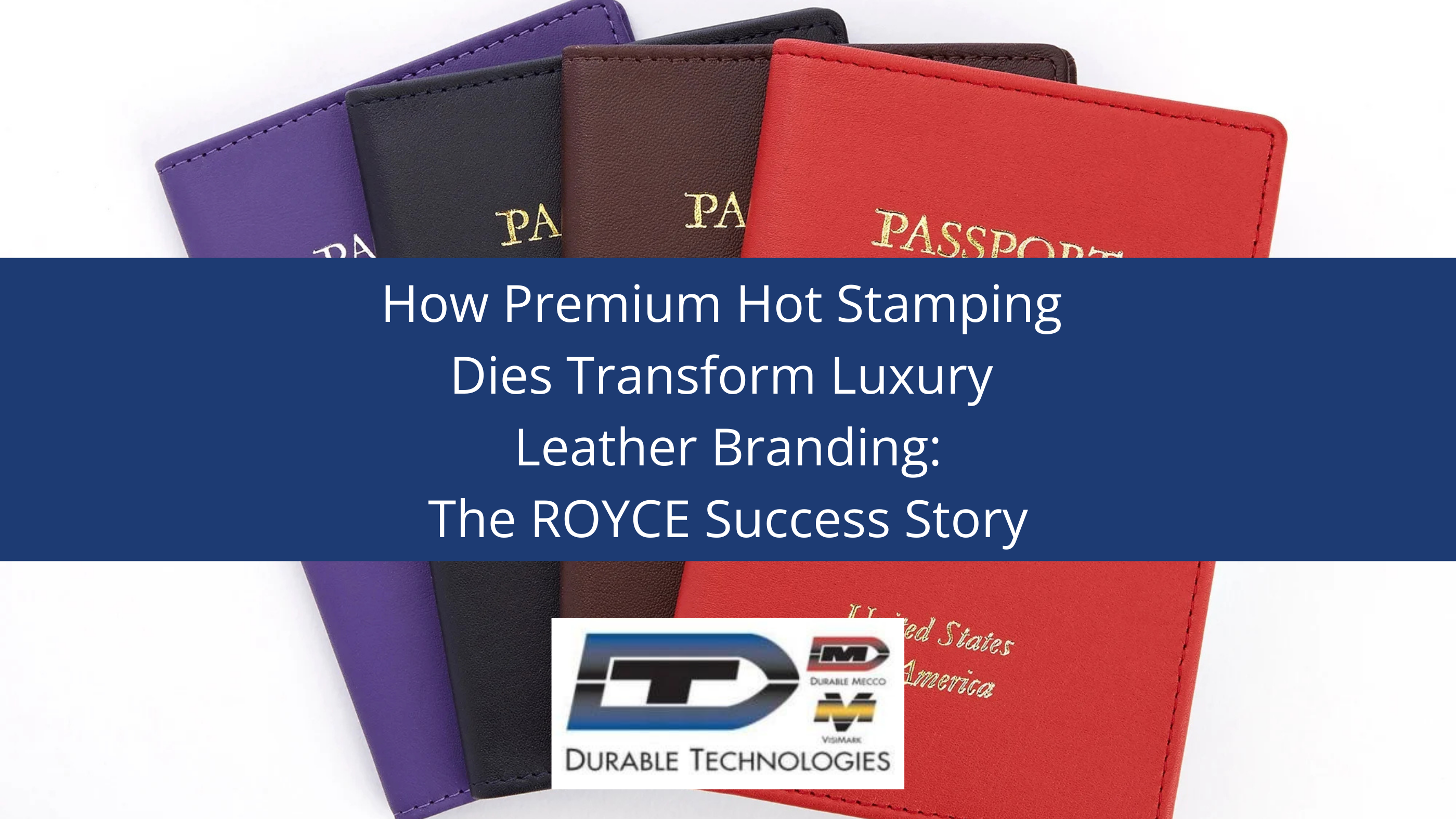

The company processes over 40,000 passport cases annually, requiring dies that maintain precision from the first impression to the forty-thousandth. This volume demands exceptional durability without sacrificing quality. Each stamped impression must exhibit clean lines and flawless quality, meeting the expectations of high-end clients who view branding as an integral part of product value.

Beyond passport cases, Royce applies hot stamping across their extensive product range. Corporate gifts receive custom logos that reinforce brand identity. Personal monogramming transforms standard products into bespoke items. The versatility of their hot stamping capabilities allows them to accommodate both large corporate orders and individual customization requests without compromising quality or efficiency.

Why Do Brass Hot Stamping Dies Matter for High-Volume Production?

The choice of brass for hot stamping dies proves particularly significant in high-volume leather goods production. Brass offers an optimal combination of thermal conductivity, durability, and precision retention that other materials struggle to match. The metal's properties allow for rapid heat transfer, ensuring consistent temperature throughout the stamping process while maintaining dimensional stability across thousands of impressions.

VisiMark's brass dies demonstrate exceptional longevity in production environments. The precision machining process creates dies with exact tolerances that resist wear even under continuous use. This durability translates directly to consistent product quality and reduced production downtime for die replacement or maintenance.

The thermal properties of brass also contribute to energy efficiency in production. The material heats quickly and maintains temperature uniformly, reducing cycle times and improving throughput. For manufacturers like Royce processing tens of thousands of units, these efficiency gains compound into significant productivity advantages.

What Hot Stamping Products Does VisiMark Create for Royce?

VisiMark manufactures a comprehensive range of hot stamping products tailored to Royce's specific requirements. Their printers type comes in both 24-point and 36-point sizes, available in Goudy and Hutch (News Gothic) style fonts. These classic typefaces provide the elegance and readability essential for luxury goods branding.

Beyond traditional alphanumeric type, VisiMark produces custom emoji dies that enable Royce to incorporate contemporary design elements into their products. These specialized dies allow for creative personalization options that appeal to younger demographics while maintaining the quality standards expected of luxury goods.

The manufacturing process for each die involves precise engraving techniques that create sharp, well-defined edges. This precision ensures that even fine details reproduce clearly in the finished impression. The depth of engraving is calibrated to the specific requirements of leather marking, creating impressions that are prominent without compromising the integrity of the material.