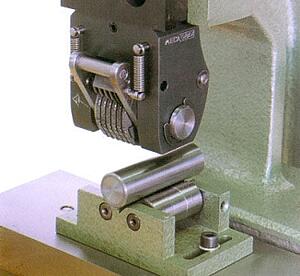

Hand stamping presses are easy-to-use, low-maintenance marking solutions that can be found in a wide range of industries and settings.

What Can a Hand Stamping Press Be Used For?

Hand stamping presses are incredibly versatile tools that can be utilized for a variety of applications beyond just basic stamping. In addition to part marking, manual impact presses can also be used for processes such as riveting, punching, and piercing.

These presses are capable of handling tasks like staking, forming, bending, crimping, assembling, broaching, and coining, making them indispensable in a wide range of industrial and manufacturing settings.

The adaptability of impact presses is a key factor in their widespread use across different industries. Whether it's shaping metal, joining materials, or creating intricate designs, hand-operated impact presses offer a reliable and efficient solution for a multitude of tasks.

Their ease of use, low maintenance requirements, and consistent results make them a valuable asset for any production environment.

Manual versus Pneumatic Presses

While pneumatic impact presses may offer advantages for high-volume applications, hand-stamping impact presses have their unique benefits.

Manual presses are not only easy to set up and operate with minimal training, but they also provide a level of control and precision that automated solutions may lack.

In addition, manual impact presses are known for their reliability and safety, making them a popular choice for industries where quality and accuracy are paramount.

These presses are perfect for low-volume requirements where cycle time is not a pressing concern, as they can deliver consistent results without the need for complex automation.

Ultimately, the choice between manual and automated impact presses depends on the specific needs of the application.

While automated solutions may be more efficient for high-volume production, manual presses offer a level of versatility, control, and reliability that can be invaluable in certain settings.

It's important to carefully consider the requirements of the task at hand when selecting the right type of impact press for your operation.

Learn More

To learn more about specifying and selecting an impact press, please check out our post "How Do You Select an Impact Press". To see how Durable Technologies can improve your manufacturing and assembly processes, please contact us today.