2 min read

Using a Branding Iron: The 5 Things You Need to Know

Matt Martin

Tue, Apr 02, 2024 @ 13:04 PM

Branding irons, those iconic emblems of craftsmanship, hold a unique role in the world of marking materials. Picture a craftsman meticulously etching their mark onto a piece of fine timber or leather. This ancient practice goes beyond mere identification; it's about leaving an indelible signature, a stamp of quality and ownership.

What are branding irons used for?

But what exactly are branding irons used for? Well, think of them as the artisans' signature. They're not just tools; they're storytellers.

Whether it's adorning fine furniture with a trademark or imbuing timber with a craftsman's name, branding irons are the storytellers of the trade.

Even tools and equipment find their identity through these fiery symbols, serving both personal and security purposes.

Why use a branding iron?

Why choose a branding iron over other marking methods? The answer lies in its simplicity and versatility. Unlike costly alternatives, branding irons offer a budget-friendly solution. Crafted with ease of customization in mind, they allow for the transfer of any design onto surfaces with minimal upkeep.

Moreover, wielding a branding iron is a breeze, perfect for artists and craftsmen seeking efficiency. With a single setup, one can leave their mark on a multitude of materials. Adjusting the temperature unlocks a world of possibilities, from marking wood to plastic to leather and beyond. In essence, branding irons are more than mere tools; they're the storytellers of craftsmanship, offering a timeless and practical solution to leaving a lasting impression on the materials that shape our world.

In essence, branding irons are more than mere tools; they're the storytellers of craftsmanship, offering a timeless and practical solution to leaving a lasting impression on the materials that shape our world.

Branding Iron Temperature

In general, rubber and leather branding temperatures are between 325° to 400°F, softwoods 650° to 750°F, and hardwoods/thermoset plastics 750° to 850°F. Our branding irons are sold with optional temperature regulators to ensure consistent results.

Some testing is required to determine the optimal branding iron temperature for your unique combination of material and design.

Below you can see how quickly and easily a branding iron can be used to make a deep, lasting mark in PVC piping.

Using a branding iron

When making a branded mark with a handheld or drill press branding iron, there are five factors that determine the successful outcome of the mark:

When making a branded mark with a handheld or drill press branding iron, there are five factors that determine the successful outcome of the mark:

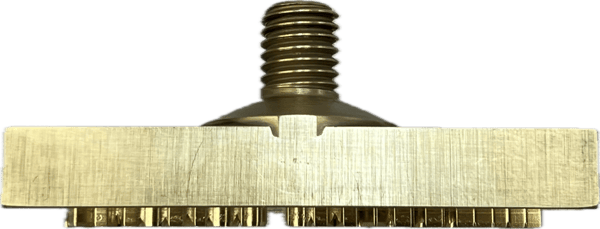

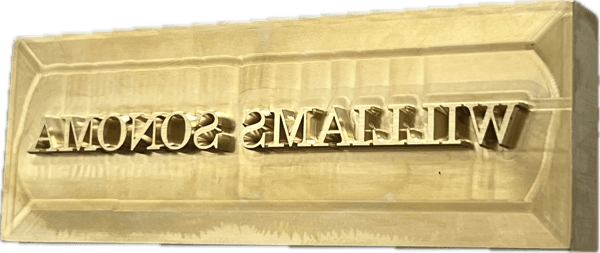

- Design- Clean, simple designs work best when branding. Busy or highly detailed art can result in less than satisfactory results. Custom bronze dies can be engraved per your artwork or provided with a pocket to hold interchangeable type or logos.

- Temperature- Temperature settings vary depending on the material to be branded.

- Pressure- Pressure must be applied uniformly to ensure deep, even impressions.

- Dwell Time- Dwell time refers to the contact time between the branding die and the material to be marked. This time is determined by the die temperature relative to the melting or burning temperature of the material.

- Depth of Brand- The longer the dwell time and the greater the pressure, the deeper the branded mark. The desired depth of the mark depends on the application requirements and the desired appearance.

Learn More About Using a Branding Iron

To learn more about successfully marking your brand using a branding iron, download our free How to Make a Quality Brand guide.

The guide will provide a detailed explanation of all five factors that make a successful brand.