2 min read

Magnesium Dies and Foil Ribbons for Hot Stamping

Matt Martin

Thu, Jan 15, 2026 @ 09:01 AM

When South Texas Lighthouse for the Blind lost its hot stamping ribbon supplier, Buyer Megan Hammock faced a problem familiar to many production managers right now. API Foils had recently closed its doors, leaving customers scrambling for replacement white ribbon that could match their existing process specifications.

Megan reached out to her industry contacts for recommendations. The response was consistent: call VisiMark.

Who Can Replace API Foils Hot Stamping Ribbon?

South Texas Lighthouse for the Blind has been providing job opportunities for individuals who are blind or have low vision since 1964. Their production floor includes modified equipment to accommodate blind operators, along with screen readers and magnifiers in their offices. STLB provides meaningful employment for people who might otherwise struggle to find work.

Megan first contacted VisiMark, a division of Durable Technologies, specifically about sourcing white hot stamp ribbon as an alternative to the API Foils formula she had been using for years. VisiMark sent samples of several white ink formulations so Megan could test them against her existing process requirements.

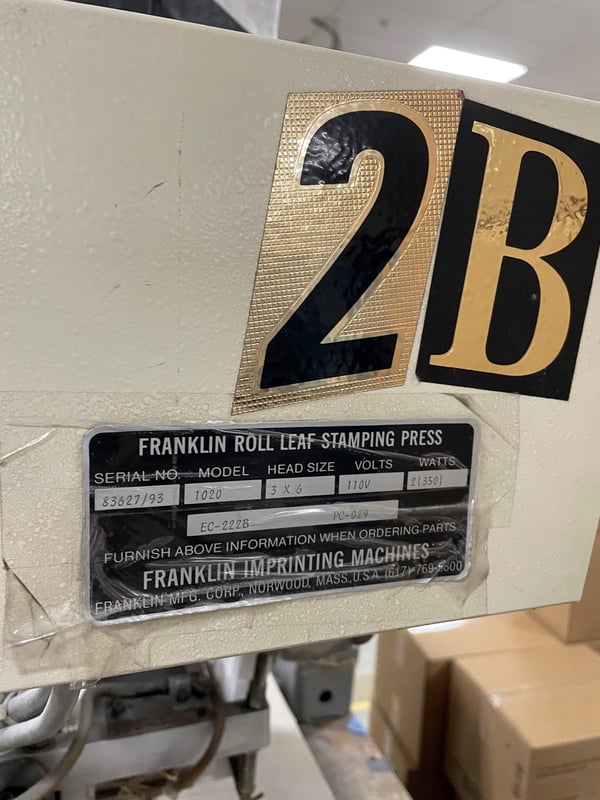

She found a formula that performed well on their Franklin Roll Leaf press, which they use for stamping poly and cardboard binders with customer logos and text.

Can You Buy Hot Stamping Ribbon and Dies From One Supplier?

Once Megan identified a suitable ribbon alternative, she asked VisiMark about magnesium hot stamp dies. STLB had been running some older dies that needed replacement, and sourcing from a single vendor would simplify their procurement process.

VisiMark was able to supply both products, allowing Megan to consolidate vendors and reduce the complexity of managing multiple supplier relationships. For production environments where ribbon and dies need to work together seamlessly, this kind of single-source approach eliminates finger-pointing when something goes wrong.

Megan says, "Everyone at VisiMark is super helpful and knowledgeable and provided nothing but great service every time we talked."

When Should You Use Magnesium Dies Instead of Brass or Steel?

Durable Technologies' magnesium imprinting dies work in just about any hot stamping or imprinting machine. The real question is whether magnesium is the right material for your specific application.

Magnesium dies are fast to produce and economical, making them ideal for shorter production runs where the upfront cost of brass or steel doesn't make financial sense. They reproduce logos and insignias with good detail, and can be deep etched or routered when you need extra relief for softer materials like leather.

Common applications include foil imprinting on leather goods, book bindings, plastics, ribbons, greeting cards, napkins, matchbooks, menu covers, jewelry boxes, Styrofoam molds, and advertising specialty items.

Magnesium dies typically ship mounted type high (.918") or unmounted in 16 gauge (.062"), 11 point (.153"), or 1/4" (.250") thicknesses.

For longer production runs where die longevity matters, brass and steel logo dies deliver better value over time. Click here for more information on choosing the right die material for your volume requirements.

What Substrates Work With Hot Stamping Foils and Ribbons?

Durable Technologies supplies a range of pigmented foils and ribbons formulated for imprinting variable data like production dates, expiration dates, lot codes, and storage information.

These foils perform well on food and pharmaceutical packaging films, coated and uncoated label stocks, polyethylene, polypropylene, polyester, nylon, wires, and heat shrink sleeving. The key is matching the foil formulation to your specific substrate and process parameters.

Need to Replace Your Current Hot Stamping Supplier?

If you're searching for API Foils alternatives or looking to consolidate your ribbon and die purchases with a single supplier, VisiMark can help. We'll send samples so you can test formulations against your current process before committing to a purchase.