1 min read

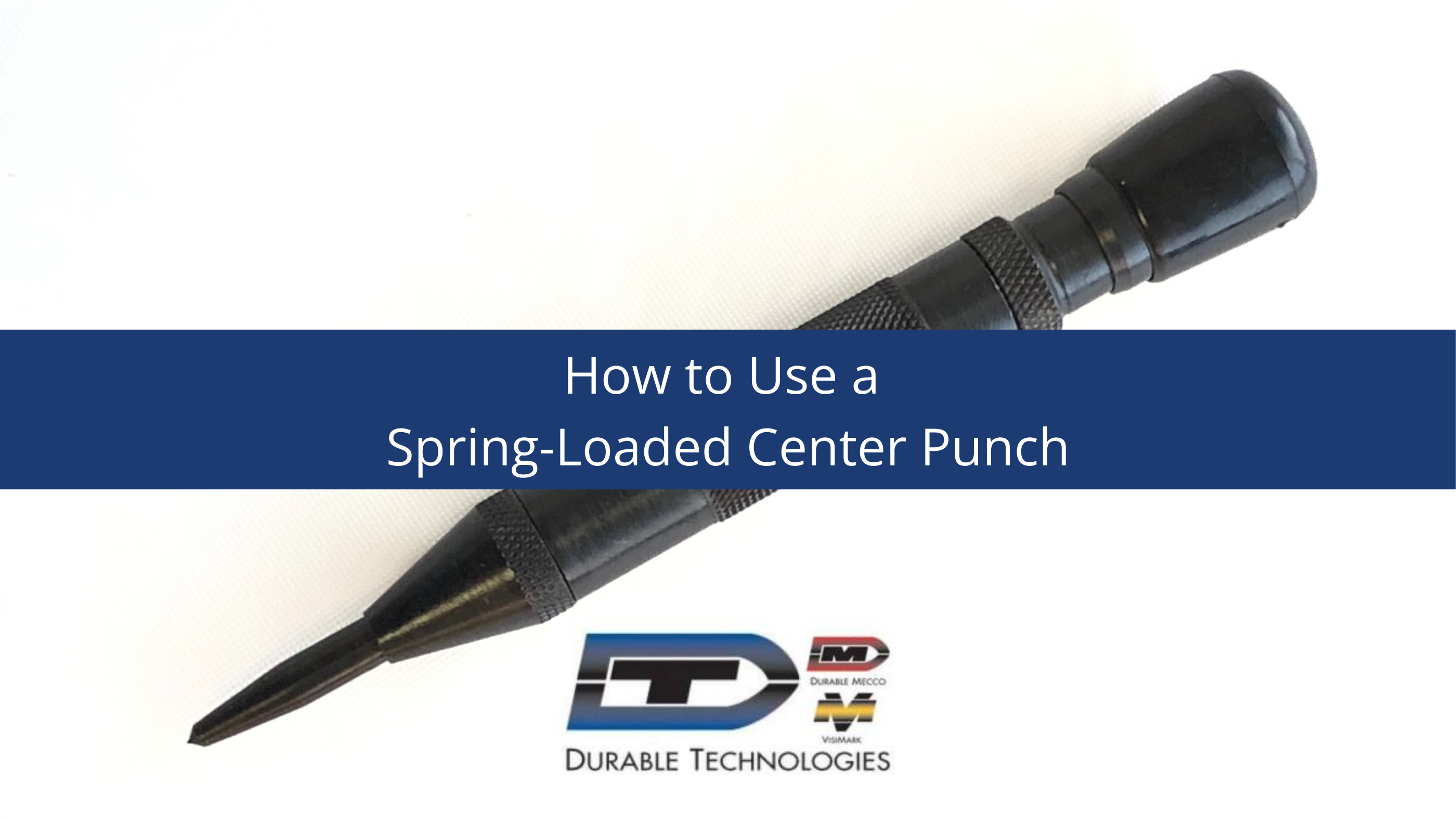

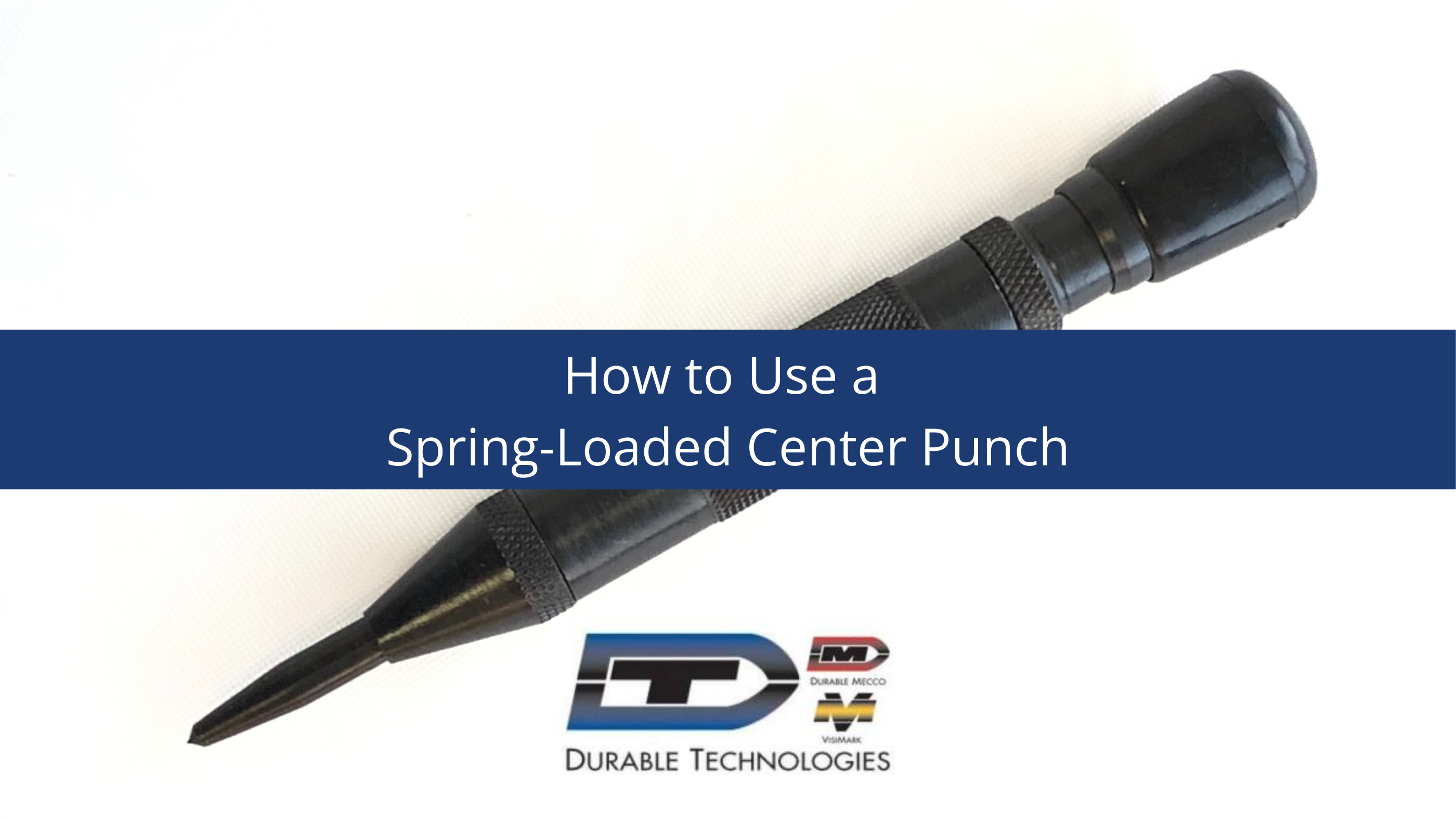

A common handheld marking tool is an automatic spring-loaded center punch. This tool produces a dimple, characters, or small symbols in a workpiece made of metal, wood, or even some plastics.

A spring-loaded center punch is used by pressing the marking end against the workpiece. A spring-loaded center punch stores energy in the spring, and as compressed it is triggered and releases the spring-stored energy as an impulse that drives the punch into the work surface, producing the dimple, character, or symbol.

A spring-loaded center punch is used by pressing the marking end against the workpiece. A spring-loaded center punch stores energy in the spring, and as compressed it is triggered and releases the spring-stored energy as an impulse that drives the punch into the work surface, producing the dimple, character, or symbol.

Durable Technologies’ center punch marking tool, with its calibrated spring-loaded action, requires only hand pressure to make a mark.

We have developed quick change inserts to create alphanumeric character center punches, custom symbol center punches, or even a custom logo center punch (3/16" height max).

The overall length of our spring-loaded center punch tool is 6”, including the insert. The center punch can also be integrated into a pre-built fixture to make a simple pass/fail mark, machine code, or other direct part identification marking.

Our spring-loaded center punch requires a minimum force of 25 lbs. to make a stamped mark. The maximum force is approximately 225 lbs. for larger characters and deeper marks.

A spring-loaded center punch is often used to mark the center of a point to show the center of a hole when drilling, for example. A center punch forms a dimple large enough to direct the tip of the drill to the proper location.

Click here to download our Symbol Chart.

Gif courtesy of https://en.wikipedia.org/wiki/Automatic_center_punch