Durable Technologies manufactures a wide variety of brass printers' type styles that will fit any need for monogramming, personalizing, or any other decorative printing.

Our brass printers' type is compatible with printers by Kingsley®, Kwikprint®, AAmstamp®, Kensol Franklin®, Jackson®, Gibson®, Howard®, and virtually any other hot stamping machine.

Hot stamping has become an increasingly versatile marking solution that serves countless industries seeking professional personalization and branding capabilities. The range of applications continues to expand as businesses discover new ways to differentiate their products through direct marking techniques.

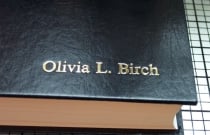

Bookbinding and Publishing Applications

Professional bookbinders rely on hot stamping for creating elegant spine lettering, cover designs, and decorative elements that give publications a premium appearance. Whether working with leather-bound classics, limited edition volumes, or custom photo albums, hot stamping provides the crisp, permanent marking that traditional bookbinding demands. The process works exceptionally well on various book materials, from genuine leather to synthetic covers, allowing artisans to create everything from wedding albums to corporate presentations with sophisticated branded elements.

Personalization and Custom Gift Markets

The personalization industry has embraced hot stamping as a cornerstone technology for creating memorable custom items. Wedding favors, anniversary gifts, corporate awards, and promotional items all benefit from the professional appearance that hot stamping delivers. Business owners operating in the custom gift space find that hot stamping allows them to offer on-demand personalization services, creating everything from monogrammed jewelry boxes to personalized picture frames with minimal setup time between orders.

Textile and Fashion Applications

Ribbons and fabric marking represent substantial market segments where hot stamping excels beyond traditional printing methods. Satin ribbons for floral arrangements, grosgrain ribbons for packaging, and decorative trim for garments all receive professional marking through hot stamping processes. The technique works particularly well on synthetic fabrics where other marking methods might fail, creating permanent impressions that maintain their appearance through repeated handling and environmental exposure.

Paper Products and Stationery

Greeting card manufacturers, invitation designers, and specialty paper product companies utilize hot stamping to create premium finishes that command higher price points. The process adds metallic accents, embossed textures, and custom logos to everything from wedding invitations to business cards. Napkins for special events, matchbooks for restaurants and bars, and promotional materials all benefit from the sophisticated appearance that hot stamping provides.

Labeling and Identification Solutions

Industrial labeling applications often require permanent marking solutions that hot stamping readily provides. Product labels, warning tags, identification plates, and safety markers all utilize hot stamping technology when durability and legibility are paramount. The process creates marks that resist fading, scratching, and environmental degradation better than many alternative marking methods.

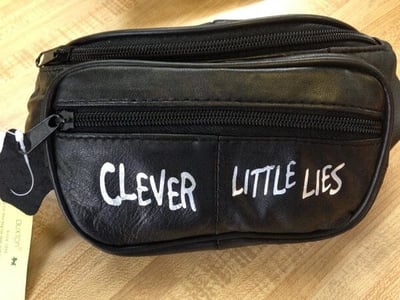

Leather Goods and Accessories

The leather industry has long recognized hot stamping as the preferred method for creating professional marks on finished goods. Wallets, belts, handbags, and briefcases all receive branding, personalization, and decorative elements through hot stamping processes. Custom leather craftsmen particularly appreciate how hot stamping allows them to add professional finishing touches to handmade items, creating products that compete with mass-produced alternatives.

Advertising and Promotional Items

Specialty advertising companies utilize hot stamping for creating memorable promotional products that help businesses stand out in competitive markets. Promotional pens, corporate gifts, trade show giveaways, and branded merchandise all benefit from the professional appearance and durability that hot stamping provides. The process allows advertising agencies to offer premium customization services that enhance brand visibility and customer retention.

Superior Material Quality and Longevity

The foundation of effective hot stamping lies in using premium materials that deliver consistent results over extended production runs. High-quality brass type and dies represent a significant advantage over cheaper alternatives that compromise both appearance and longevity. While zinc and lead alloys might initially seem cost-effective, they typically fail under regular production use, creating inconsistent impressions and requiring frequent replacement.

Brass type maintains its dimensional accuracy and surface finish through thousands of impressions, ensuring that each mark matches the quality of the first. This consistency becomes particularly important for businesses building brand recognition, where variations in mark quality can undermine professional appearance and customer confidence. The initial investment in quality brass materials pays dividends through reduced downtime, fewer replacement costs, and consistently superior results.

Comprehensive Customization Capabilities

Modern hot stamping services extend far beyond standard alphabetic characters, offering complete customization solutions for businesses with unique marking requirements. Custom type production accommodates any style typeface or font, including specialized applications like Optical Character Recognition (OCR) fonts used in automated sorting and tracking systems.

International businesses benefit from foreign language character sets that allow for global product marking without compromising quality or appearance. Whether marking products for European markets, Asian distribution, or specialized technical applications, custom type ensures that every character maintains the same professional standards as standard English lettering.

Logo reproduction through hot stamping dies creates opportunities for brand reinforcement across product lines. Complex corporate logos, intricate artistic designs, and specialized symbols all translate effectively to hot stamping applications when produced by experienced die manufacturers. The process captures fine details while maintaining the durability necessary for production environments.

Custom symbol creation serves specialized industries with unique marking requirements. Technical symbols, safety markers, industry-specific icons, and regulatory markings all benefit from custom die production that ensures compliance and professional appearance. This flexibility makes hot stamping particularly valuable for manufacturers serving multiple markets or regulatory environments.

The combination of diverse applications, superior materials, and comprehensive customization capabilities positions hot stamping as an essential technology for businesses seeking to enhance their products through professional direct marking. Whether serving traditional markets or exploring new applications, the technique continues to evolve while maintaining the quality and reliability that have made it indispensable across numerous industries.